a proven tyre management tool that quickly identifies the best tyre for the job

When we talk about Total Tyre Control™ (TTC) this is what we're referring too. TTC Earthmover is the core TTC product, most other TTC products are add-ons to TTC Earthmover.

TTC Earthmover tracks tyres and rims, it provides in depth information on tread wear, tyre usage, manufacturer comparison and more.

TTC Earthmover puts you in charge of your tyres and rims, while promoting increased safety levels and increased fleet production at a lower tyre cost.

TTC Earthmover is a proven tyre management tool (established in 1987) that quickly identifies the best tyre for the job, schedules and monitors day to day tyre maintenance, reports on tyre performance and condition (both on screen and printed) and includes accurate tyre budget forecasting.

TTC Earthmover will perform tyre brand comparisons, project inventory needs, evaluate repair and retread performance, monitor casing age, flag tyre warnings, detect possible mechanical problems and calculate cost per kilometer (or mile) based on actual tyre performance.

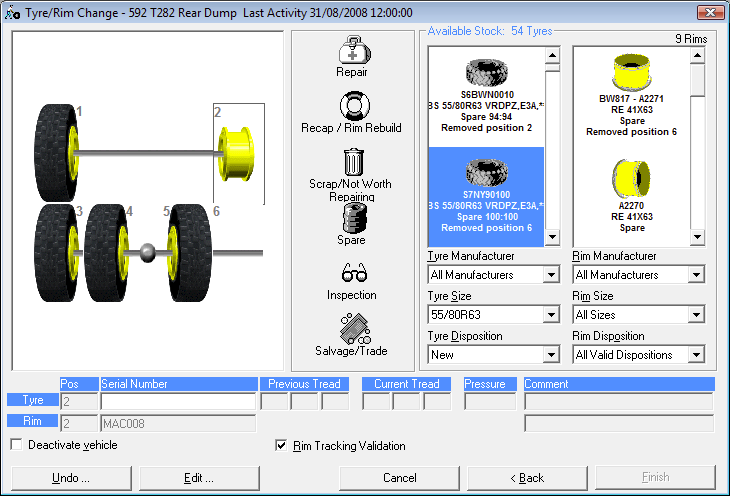

Total Tyre Control™ provides easy-to-use, intuitive interfaces featuring process related steps to mimic real-life actions.

Figure 1 – A Vehicle Tyre Change in Total Tyre Control™ – drag-and-drop, userfriendly data-entry that mimics real-life actions.

TTC Earthmover is designed to:

- Identify the Best Tyre for the Job.

- Project Tyres Required (Budget).

- Calculate Tyre Delivery Schedule.

- Monitor Tyre-Related Downtime - Scheduled versus non-Scheduled.

- Allow immediate real-time comparison of different tyre brand results, including retreads.

- Eliminate the need for time-consuming manual record keeping.

- Calculate tyre cost per kilometre/mile and per hour simultaneously.

- Provide retread whole-of-life and/or current life performance/cost analysis.

- Promote better communication between tyre owners and tyre manufacturer/sales outlets and will reduce your tyre bill.

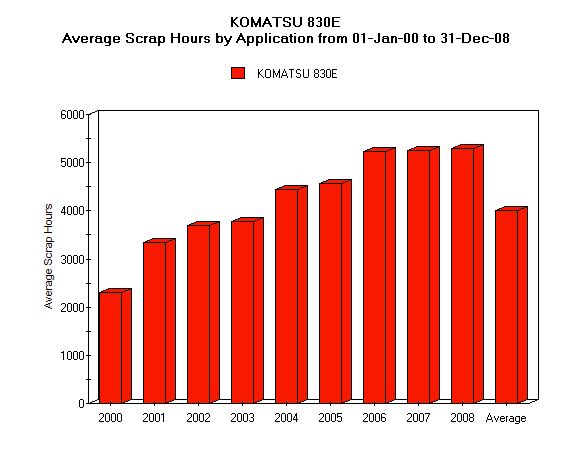

Figure 2 – Average Scrap Hours translates to the average operating life of a tyre. Seen here, from 2000 to 2008, Total Tyre Control has assisted is doubling the operating life of the Komatsu 830E trucks.

Proactive and Preventive Management

Total Tyre Control™ presents a comprehensive set of functionalities and reports to promote proactive management practices and facilitate the prevention of tyre and rim damage.

Modelling features allow Total Tyre Control™ users to forecast new tyre demand. Through simulations based on historical and definable forward planning parameters (i.e. ‘what if’ scenarios), the tyre forecasting tool is essential in establishing the risk of tyre shortages that lead to unnecessary decrease in production.

Total Tyre Control™ software analyses and reports on tyre and rim failure trends, identifies reasons for failure and provides the user with tyre and rim maintenance alerts. Such alerts maintain proactive management practices by warning the user of tyre and rim maintenance requirements.

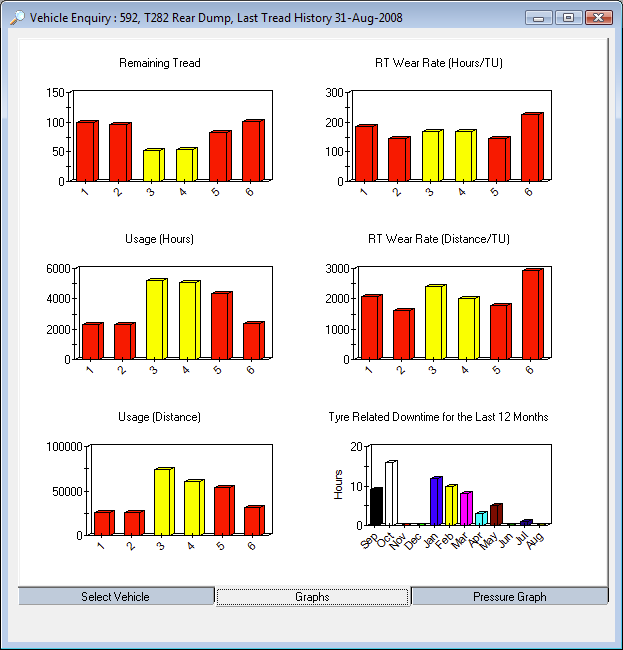

Figure 3 – Various Graphs available under the Vehicle Enquiry. Note the different colours of the bar charts to represent different tyre manufacturers.

Functionality and Reporting

Total Tyre Control™ is the most comprehensive tyre and rim asset management tool in the market today. Some of its reporting and analysis features include – but are not limited to:

- Tread Audits

- Analysis of Tyre Performance by tyre manufacturer, tyre type, vehicle brand and type.

- Tyre Pressure and Temperature

- Tyre Rotations

- Rim Usage

- Tyre Forecasts

- Budget Forecasts

- Delivery Schedules

- Scheduled Maintenance Alerts

- Tyre Pressure Alerts

- Tyre Tag Tracking

Minimum System Requirements

Windows XP Systems - 1 GHz CPU, 512 MB RAM, 1024 x 768 display.

Windows Vista Systems - 1 GHz CPU, 1 GB RAM, 1024 x 768 display.

Databases

TTC Earthmover is available with Microsoft SQL Server or Microsoft Access databases.

Languages

Total Tyre Control™ is available in the following languages:

- English

- Spanish

- Portuguese

- French

- Indonesian (partial implementation)